Scotland’s barley roots

The old road to Alloa

Richard Croasdale

Photos:

Crisp Malt

Saturday 29 July 2023

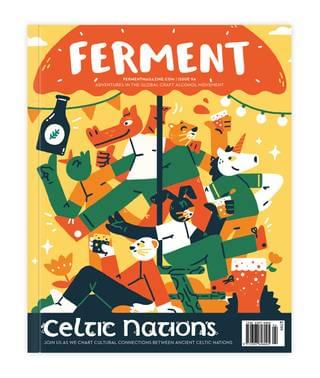

This article is from

Celtic Nations

issue 94

Share this article

The tradition of alcohol production in Scotland stretches far back beyond recorded history, to a time when the ancient Celts brewed beer from excess grain and distilled it into clear, potent uisge beatha (a gaelic name meaning ‘water of life’), the spirit that would eventually evolve into Scotch Malt Whisky. While the majority of Scottish-grown malted barley still ends up in a whisky bottle, the explosion of craft brewing north of the border has increased demand for local brewers’ malt.

Colin Johnston of Crisp Malt explains that, traditionally, the barley used for whisky production – in which the ‘yield’ of fermentable sugar is a key selection criteria – hasn’t always also been suitable for brewing tasty beer. With more modern varieties though, this isn’t necessarily the case.

Colin says: “We’re fortunate these days, in that we have these dual purpose varieties, which have been approved for distilling and for brewing, including Laureate, the main variety grown in Scotland now, accounting for about 80% of the crop. It gives very good sugar content, which produces the high alcohol yields whisky makers look for, but we can use that exact same variety for making Pale Ale malt. So for me that's quite an intimate connection to the Scottish distilling industry, and to the long history of Scottish malting and alcohol production.”

Most people probably think of Crisp as an English maltster, having been founded there more than 150 years ago. But it has a good history of malting in Scotland too, starting with its first Scottish maltings in Speyside, near Portgordon, in 1979, opened to support the fast-growing distilling industry.

“That was very much on the distilling side though,” explains Colin. “On the brewing side, it wasn’t until 2003 that we purchased our maltings in Alloa. That place has a very interesting history with the brewing industry, dating back to the 1890s, when it was a traditional floor maltings, built by George Younger of the famous brewing family. In those days, Alloa had access to good barley, it was close to Glasgow, Stirling and Edinburgh, with good train connections and a good soft water source; it became a real brewing powerhouse, probably second only to Edinburgh.”

The Alloa site continued as a floor maltings right up until the 1960s, when it was purchased by Bass and was converted into a modern ‘pneumatic’ maltings. “It’s really interesting when you go around the Alloa maltings, because all the original wooden floors are still there,” continues Colin. “The structure of the building is from the 19th century, but then you have this modern 1960s malting plant that has been shoehorned into the building. There's stairs all over the place and it's a bit of a rabbit warren.”

Bass at that time also owned Glasgow’s iconic Tennent’s brewery, which by the 1990s was taking all of its malt from Alloa. This ended when Bass sold Tennent’s to Belgium’s Interbrew (now part of AB-InBev) in June 2000; Tennent’s malt became part of the drinks giant’s global supply chain and the Alloa maltings was mothballed.

“This is where Crisp came along and saw an opportunity to revive the maltings, bring back those jobs, and supply Scotland’s small but growing brewing industry,” says Colin. “It was only shut a year before we bought it. Our logistics director at the time, Rob Moody, was literally given a giant set of keys and told he had three months to get it running. So the team went out into the local town, into the pubs, trying to find people who had worked at the site, to ask them to come and work with us again. And that’s exactly what happened.”

Crisp’s Alloa maltings is quite diverse in the malts it produces, simply because of the markets it serves. A good chunk of its output is diastatic power malt, a relatively niche product, favoured by the grain whisky industry because of the rate at which its starches break down into fermentable sugar. It also produces pot still malt – primarily for the Scotch Malt Whisky market – and, of course, brewers malt.

The final big change in how Crisp serves the Scottish industry came just ahead of the pandemic. Having always operated from its main headquarters in the South of England, Crisp found the long journey to Scotland was increasingly problematic, both financially and environmentally. Its solution was to reduce food miles and its haulage bill by opening a packaging line in Scotland, specifically catering to customers who needed their malt delivered in sacks rather than by the container-full; in other words, Scotland’s craft breweries.

“We’re now the only large maltster that grows, malts and packages in Scotland, and that’s been a great success,” Colin continues. “We now have a really fantastic customer list, including Williams Brothers right here in Alloa, Harviestoun and Stewart Brewing. I think one of the things these breweries – and their customers – really appreciate is that the Alloa supply chain is very local; 100% of our malt is Scottish spring barley, supplied from the local area, so it has that provenance and is very sustainable in terms of food miles.

“We’re very proud of that, and I think just proud to be continuing the history of Scottish malting in Alloa, with a team of local guys who've all been there forever. By collaborating with our friends at William’s Bros just down the road on this Alloa Scottish Pale Ale for Beer52, we really see this as an opportunity to celebrate our people, celebrate our local barley and share a great Scottish beer with people across the UK.”

Share this article